R&D in Three Key Areas

In fulfilling its commitment to enhancing the technological competitiveness of SMEs and contributing to the growth of Korea's manufacturing industries, KITECH focuses on three key research areas: Intelligent manufacturing & materials technology, Human-centric manufacturing technology, and Sustainable development technology. KITECH strives to strengthen the fundamentals of Korean industries by carrying out demand-oriented R&D and application activities and securing original technologies for the future.

Intelligent manufacturing & materials technology

Human-centric manufacturing technology

Sustainable development technology

Human-centric manufacturing technology

Human-centric manufacturing technology discovers future growth engines and creates new markets by facilitating convergence between technologies considering human needs, preferences, and better lives in the manufacturing process and product service development stages. KITECH's research groups focus on Human-Centric Robotics, Autonomous Manufacturing & Process, User Convenience technology, Safety Convergence technology, and Textile Innovation technology are trailblazing a path toward a new future.

Major research achievements

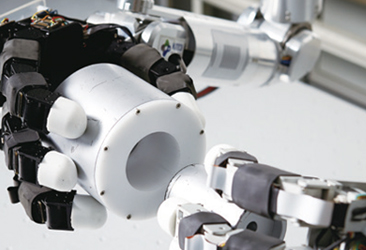

Manipulation and assembly technology using an upper body humanoid robot

Highlights

Developed a design and manufacturing technology for an upper body humanoid robot built to represent the hands and arms of a human

Developed a technology that recognizes environmental information and secures stability so as to foster cooperation with humans

Developed a technology that enables the intelligent manipulation and assembly of objects using both the hands and arms of a robot

KITECH's upper body robot displays 50 degrees of freedom (DOFs) in contrast to only 38 DOFs by existing humanoid robots (based on whole body)

Benefits

Development of the world's first precision manipulation and assembly technology (0.05 mm) using robots is expected to help companies secure technological competitiveness

Robots developed with this technology can stand in for workers to handle dangerous and strenuous tasks at manufacturing sites

The said technology was transferred to SimLab, and more than 30 units have been sold to R&D centers and universities around the world

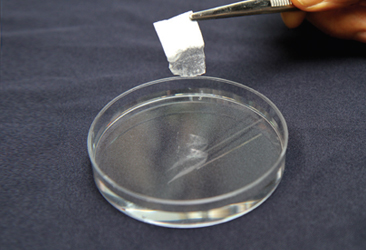

Biomedical fiber for wound healing and tissue regeneration

Highlights

Developed wound-healing functional materials using carboxymethyl cellulose derivatives (CMC)

Developed temporary skin substitutes using electrospinning technology

Developed a bio tissue regeneration system using biodegradable 3D fiber structures

Benefits

This fiber manufacturing platform technology is expected to boost productivity

Potential for the development of various types of formulations with outstanding wound-healing and tissue-regeneration functions to follow

Domestic production of high value-added medical products is expected to replace imports and create advanced medical markets

Transfer of core technology should help SMEs enhance technological competitiveness

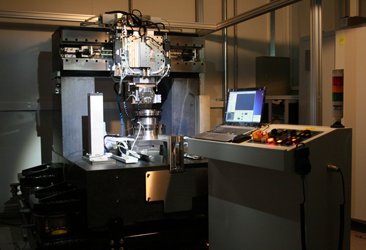

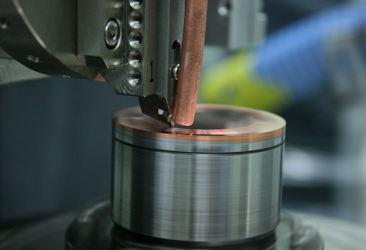

Original technology in cutting and machining for ultra-precision optical lenses

Highlights

Developed an original technology for cutting and machining 700 mm or smaller micro patterns on ultra-precision optical lenses

Used in-house developed cutting and machining equipment that can control movements down to 1 mm to develop the micro pattern cutting and machining technology

Benefits

With this technology, companies can compete with global firms in the virtual and augmented reality markets, estimated at KRW 117 trillion in 2020

This world-class technology is anticipated to be applied to high value-added products, such as infrared cameras for self-driving cars, head up displays (HUD), and hyper-spectral lenses that can penetrate geographic features